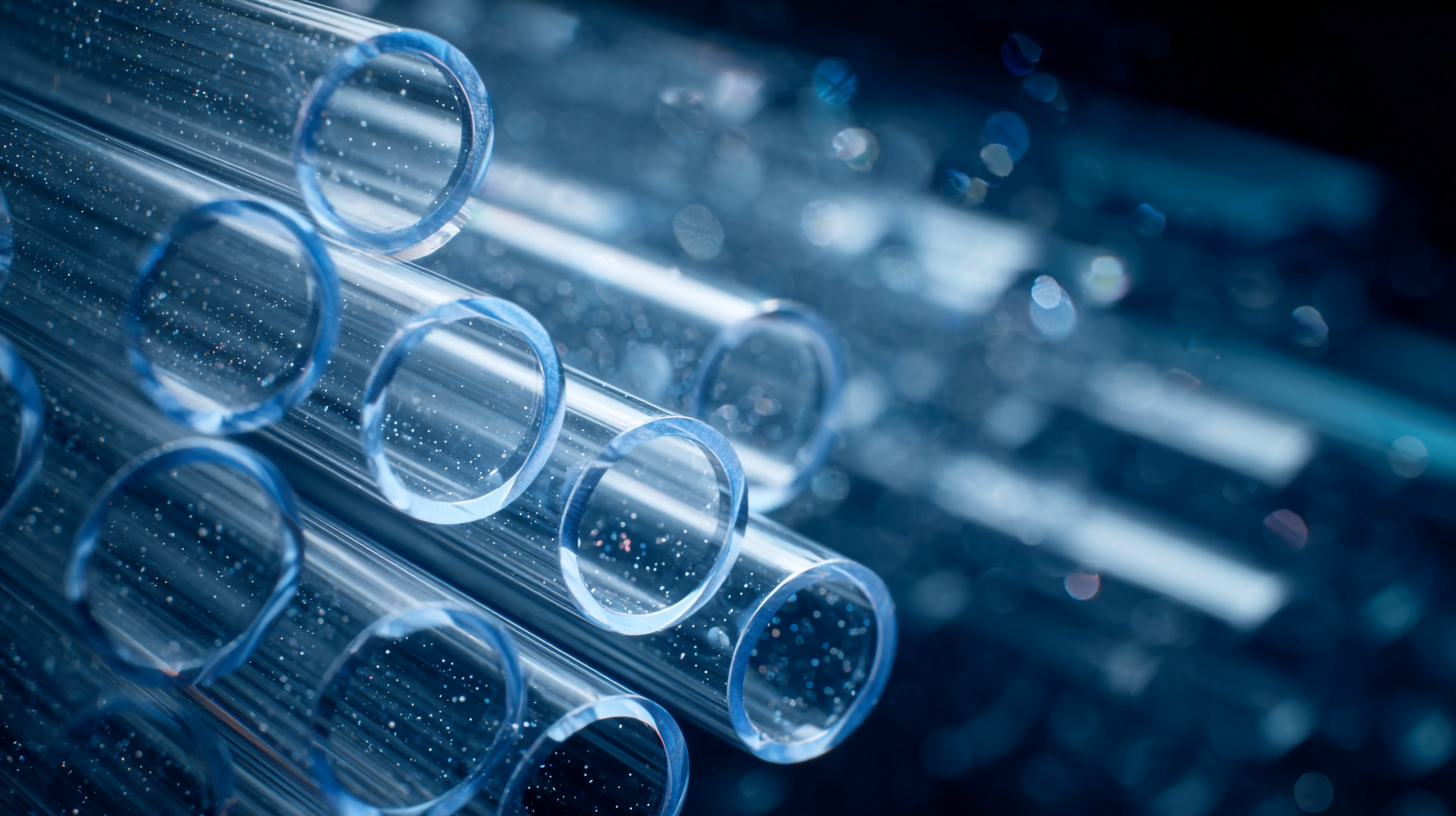

The Versatile World of Plastic Tubes: Innovations and Applications in Everyday Life

In today's dynamic landscape, the versatility of plastic tubes has significantly impacted various industries, showcasing their indispensable role in everyday applications. According to recent market research, the global plastic tube market was valued at approximately $5.4 billion in 2022, with projections indicating a robust growth rate of 4.5% through 2030. This surge is driven by the increasing demand for lightweight, durable, and cost-effective packaging solutions across sectors, including cosmetics, pharmaceuticals, and food & beverages.

The innovation found in plastic tubes has led to advancements in functionality and design, enabling brands to enhance user experience while adhering to sustainability standards. As consumers become more environmentally conscious, the industry is witnessing a shift towards recyclable and biodegradable materials, further expanding the scope of plastic tubes in modern lifestyles. This article delves into the innovations and myriad applications of plastic tubes, reflecting their profound influence on the way we live and interact with products daily.

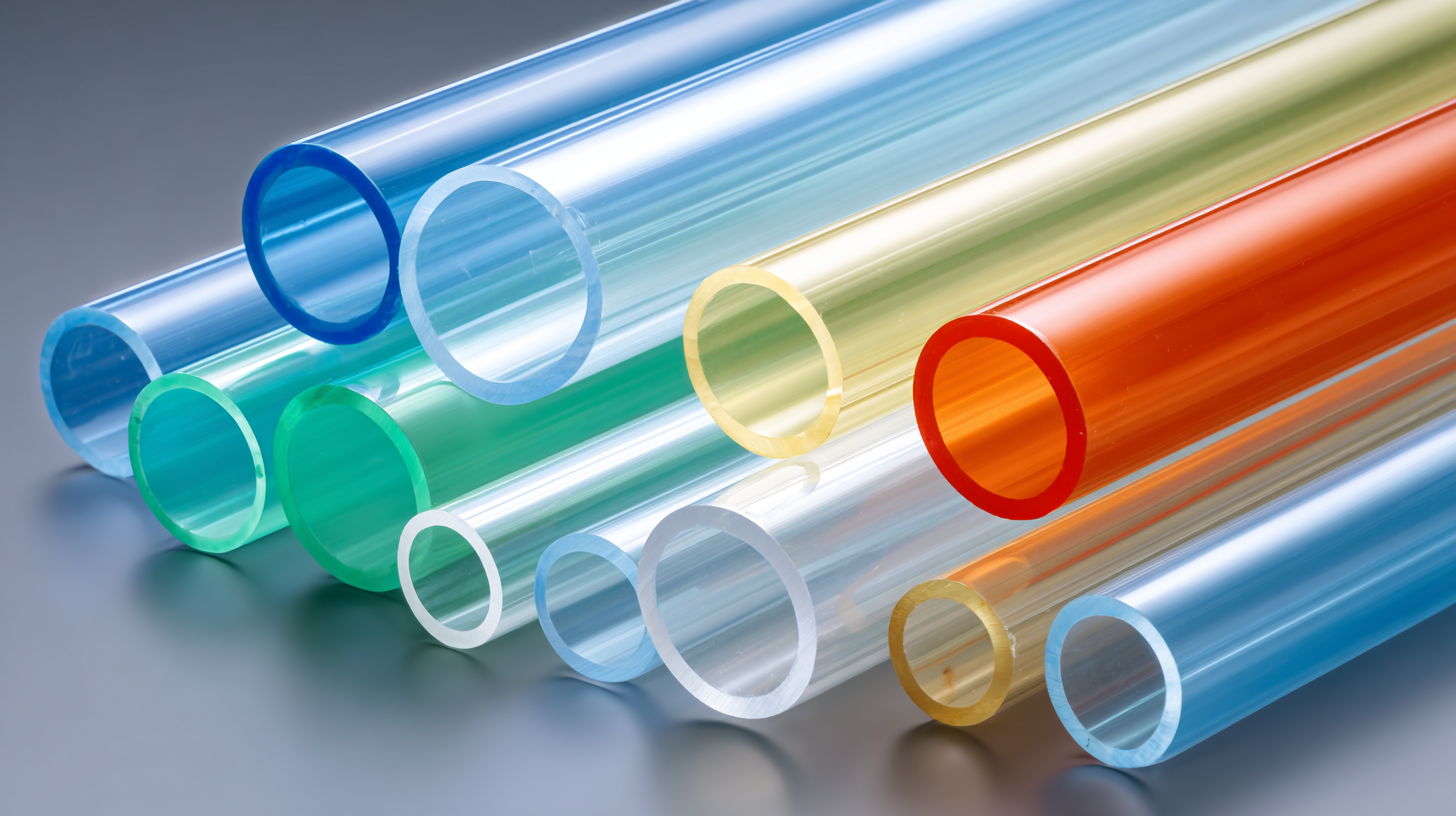

The Evolution of Plastic Tube Materials: From PVC to Bioplastics

The evolution of plastic tube materials has significantly transformed the landscape of various industries. Traditional materials like PVC have dominated for decades due to their durability and cost-effectiveness. However, growing environmental concerns have prompted a shift towards more sustainable alternatives, such as bioplastics. According to a recent report by the European Bioplastics Association, the global bioplastics market is expected to reach approximately $28 billion by 2025, highlighting a substantial rise in demand for eco-friendly materials.

As industries increasingly adopt bioplastics, the advantages are clear. Not only do these materials reduce reliance on fossil fuels, but they also minimize carbon footprints. For instance, bioplastics made from renewable resources can lead to a reduction in greenhouse gas emissions by 30-80%, depending on the material and production process used. This shift is especially relevant in application sectors such as packaging and medical devices, where sustainability is becoming a critical factor in product development.

**Tip:** When selecting plastic tubes for your projects, consider the specific material's environmental impact. Opt for bioplastics when possible, as they offer similar functionality to traditional plastics while contributing to sustainability efforts.

**Tip:** Stay informed about innovations in plastic materials, as the industry is continually evolving. Understanding the properties of new materials will help you make better choices tailored to your needs.

The Evolution of Plastic Tube Materials

This chart illustrates the popularity index of various plastic materials used in tube manufacturing, highlighting the shift towards bioplastics as a sustainable option.

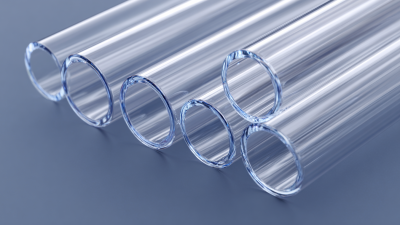

Innovative Applications of Plastic Tubes in Healthcare: A Market Overview

Plastic tubes have become integral in various industries, notably in healthcare applications. These versatile tools are utilized for packaging medicines, administering treatments, and ensuring sterile environments. The pharmaceutical packaging market illustrates this trend, where plastic materials play a dominant role due to their lightweight, durability, and ability to safeguard products from contamination. Innovations like tamper-evident designs and child-resistant features in plastic packaging are enhancing user safety and compliance.

Plastic tubes have become integral in various industries, notably in healthcare applications. These versatile tools are utilized for packaging medicines, administering treatments, and ensuring sterile environments. The pharmaceutical packaging market illustrates this trend, where plastic materials play a dominant role due to their lightweight, durability, and ability to safeguard products from contamination. Innovations like tamper-evident designs and child-resistant features in plastic packaging are enhancing user safety and compliance.

Tips: Consider exploring sustainable options in plastic tube manufacturing to cater to environmentally conscious consumers. Engaging with suppliers who prioritize recycling and the use of post-consumer materials can enhance your brand's sustainability profile.

The rise of biodegradable materials, such as Poly Butylene Succinate, marks a significant shift towards sustainable practices within the industry. This not only provides an environmentally friendly alternative but also addresses consumer demand for greener packaging solutions. As healthcare continues to evolve, exploring innovative applications for plastic tubes will be vital to meeting regulatory standards while ensuring patient satisfaction.

Tips: Stay informed on emerging materials and technologies that can elevate your product offerings. Partnerships with innovators in the field can help streamline the adoption of these advancements in your supply chain.

Sustainable Practices: The Rise of Recyclable and Biodegradable Plastic Tubes

The increasing environmental concerns have led to significant innovations in the production and use of plastic tubes. As consumers grow more aware of the ecological impact of their choices, manufacturers are responding by developing recyclable and biodegradable options. These advancements aim to reduce plastic waste that often ends up in landfills and oceans, contributing to pollution and harming wildlife. By utilizing materials that can easily break down or be recycled, these new plastic tubes provide sustainable alternatives without sacrificing functionality.

Recyclable plastic tubes are designed for easy processing through existing recycling systems, encouraging consumers to dispose of them responsibly. Innovations in biodegradable plastics, often derived from renewable resources, can decompose under natural conditions, offering a viable solution for single-use applications. This shift not only supports environmental preservation but also meets the growing demand for sustainable products across various industries, from cosmetics to food packaging. As businesses adopt these eco-friendly practices, the versatility of plastic tubes continues to evolve, aligning with a more sustainable future.

Cost Efficiency in Manufacturing: How Plastic Tubes Reduce Production Expenses

Plastic tubes have emerged as a revolutionary material in modern manufacturing, offering significant cost efficiencies that benefit various industries. Their lightweight nature reduces shipping and handling costs, making them an attractive alternative to heavier materials. Manufacturers can leverage these savings not only in logistics but also in production processes, as plastic tubes often require less energy to produce and shape compared to traditional materials.

Moreover, the versatility of plastic tubes allows for innovative design solutions that minimize waste. With advancements in production technology, manufacturers can create tubes tailored to specific needs without excess material. This precision in design helps further lower costs while ensuring high-quality performance across applications. From packaging to construction, the use of plastic tubes exemplifies how strategic material choices can lead to substantial economic advantages within an ever-competitive marketplace.

Future Trends: Smart Plastic Tubes Integrating IoT Technology in Daily Use

The integration of Internet of Things (IoT) technology into plastic tubes is set to revolutionize their applications in various industries. Smart plastic tubes, equipped with sensors and connectivity features, can monitor fluid dynamics, temperature, and pressure in real time. According to a recent Market Research Future report, the global smart tubing market is anticipated to reach $41 billion by 2027, driven by increasing demand for automation in sectors like healthcare, automotive, and agriculture.

One of the most exciting prospects of smart plastic tubes is their potential in medical applications. These tubes can deliver critical data to healthcare providers, improving patient monitoring and treatment delivery. For example, tubes used in intravenous therapies can now track and report on drug flow rates, ensuring timely interventions. This innovation not only enhances patient safety but also streamlines medical workflows, ultimately contributing to improved healthcare outcomes.

**Tips:** When selecting smart plastic tubes for your application, consider factors like compatibility with existing systems, data security features, and ease of integration. Additionally, staying updated on advancements in IoT technologies can help you make informed decisions on adopting the best solutions for your needs. Remember to engage with suppliers who offer comprehensive support and training to maximize the benefits of these innovative products.

Related Posts

-

Exploring the Future of Best Plastic Tubes Technologies in 2025 and How to Leverage Them

-

How to Choose the Right Plastic Tubes for Your Manufacturing Needs

-

Innovative Examples of Cosmetic Tubes Transforming Beauty Packaging

-

Ultimate Guide to Choosing the Right Label Tube for Your Packaging Needs

-

Essential Guide to Choosing the Perfect Lip Balm Tubes for Your Brand

-

Exploring the Rise of Eco Friendly Cosmetic Packaging at the 138th Canton Fair 2025