What is a Plastic Tube and Its Common Uses?

Plastic tubes are versatile components found in many industries. Renowned industry expert Dr. John Miller notes, “Plastic tubes are essential for efficient fluid transport.” These simple yet effective structures play a crucial role in areas such as packaging, construction, and healthcare.

In packaging, plastic tubes protect products from damage while also being lightweight. In construction, they provide means for wiring and plumbing. In the medical field, they are vital for transferring fluids safely. Each application highlights the practical nature of plastic tubes in everyday life.

Despite their advantages, the use of plastic tubes raises environmental concerns. Many are not biodegradable. Therefore, a balance must be struck between functionality and sustainability. This ongoing reflection is important for the future of plastic tubes in industry.

Definition of Plastic Tubes: Overview and Characteristics

Plastic tubes are versatile products made from synthetic materials. They come in various shapes and sizes. Their flexibility, durability, and lightweight characteristics make them popular. Often, these tubes are used in industries like construction, agriculture, and packaging.

Common uses of plastic tubes include irrigation systems and medical applications. In irrigation, they transport water efficiently. In medical settings, plastic tubes can be found in devices such as IV lines and catheters. Each application highlights the unique properties of plastic materials, which resist corrosion and are easy to mold.

Tips: When selecting a plastic tube, consider its diameter and wall thickness. Ensure it fits your specific needs. Always check compatibility with the substances it will carry. A small oversight can lead to issues down the line. Remember, not every type of plastic is suitable for every job. Do your research before making a choice.

Common Materials Used in Manufacturing Plastic Tubes

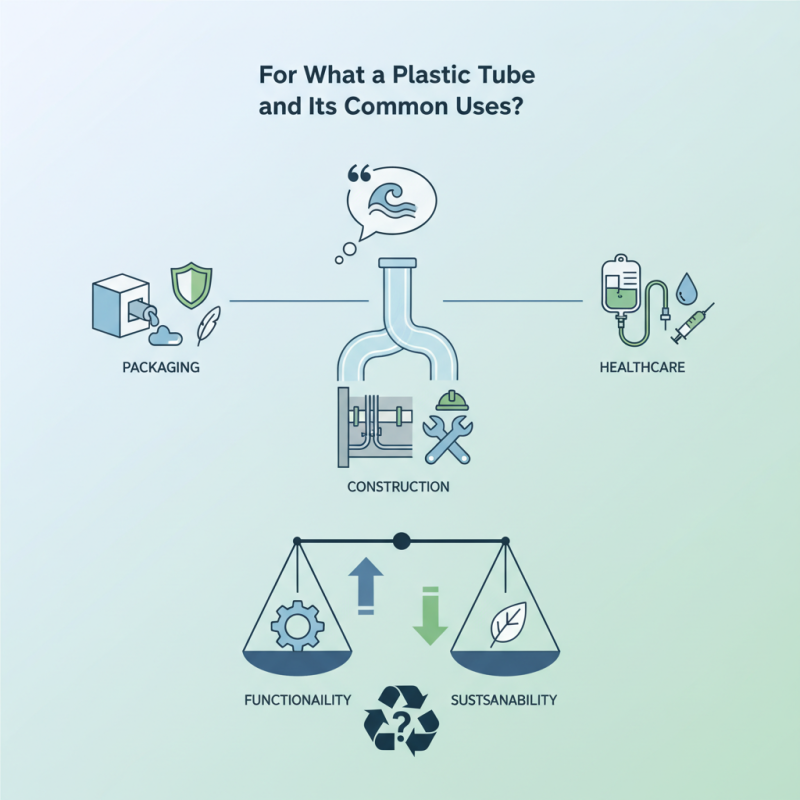

Plastic tubes are made from various materials, each suited for specific applications. Commonly used materials include polyethylene, PVC, and polypropylene. These plastics are chosen for their durability and resistance to various chemicals. According to a 2022 industry report, polyethylene accounts for about 40% of the global plastic tube market. Its flexibility and cost-effectiveness make it a popular choice in packaging and manufacturing.

PVC is another popular choice, especially in construction and plumbing. It offers excellent tensile strength and can withstand high pressures. Statistics show that the demand for PVC tubes is expected to rise by 5% annually due to urbanization and infrastructure development. Polypropylene is lighter and possesses a high resistance to fatigue. This makes it ideal for applications requiring repeated bending or movement.

While these materials are widely accepted, challenges remain. Production methods can lead to waste, and recycling rates vary significantly. The life cycle of plastic products still poses environmental concerns. As industries advance, addressing these imperfections becomes increasingly crucial. Greater awareness and innovation a necessity for sustainable growth.

Types of Plastic Tubes and Their Specific Applications

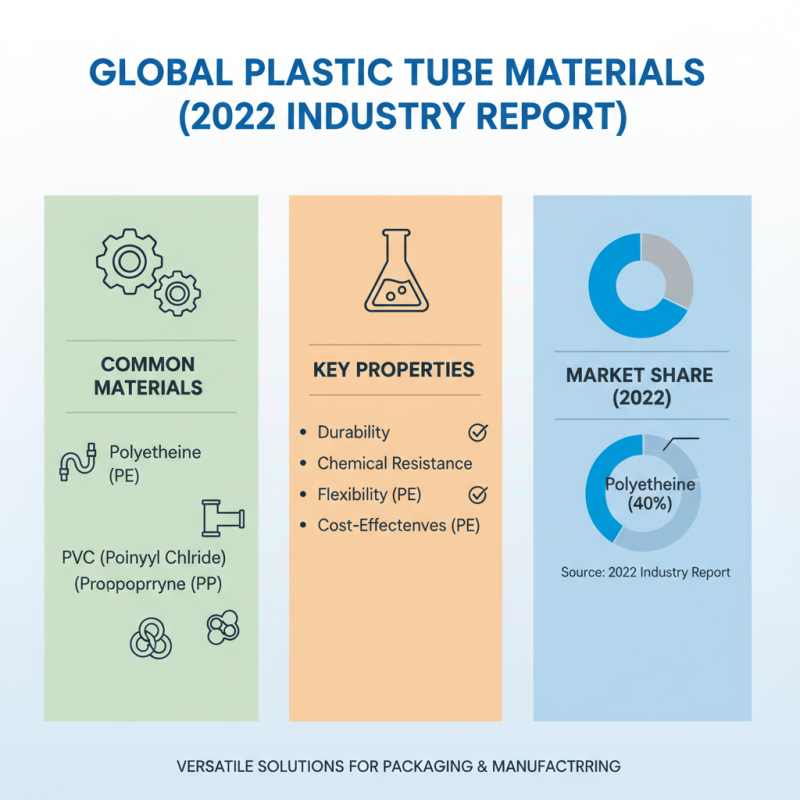

Plastic tubes come in various types, each tailored for specific applications. Clear PVC tubes are popular for their visibility. They are often used in aquariums and crafting. Designers appreciate their flexibility and durability. These tubes can withstand various pressures, making them suitable for transporting liquids.

On the other hand, polyethylene tubes are known for their chemical resistance. They are commonly used in scientific laboratories and medical settings. The tubes ensure safety when handling various substances. However, their rigidity can be a limitation in certain situations. Users may find adjusting them challenging.

Another type is nylon tubing, favored for its strength and lightweight nature. It finds applications in automotive and pneumatic systems. Yet, it can be less flexible than some prefer. This can pose challenges in intricate installations. Each type has its merits and shortcomings, prompting users to reflect on their specific needs.

Advantages of Using Plastic Tubes Over Alternatives

Plastic tubes are widely used in various industries due to several advantages over traditional materials. For instance, a report from the Plastics Industry Association shows that plastic tubes are lightweight yet incredibly durable. This characteristic makes them ideal for packaging products in sectors like cosmetics and food. They can withstand pressure and are resistant to moisture, ensuring product integrity.

Another notable advantage is cost-effectiveness. A study by Grand View Research found that the demand for plastic tubing is projected to grow by 5% annually. This growth is attributed to the low production costs and ease of manufacturing plastic tubes compared to metal or glass. Additionally, plastic tubes can be molded into various shapes and sizes, allowing for customization.

Finally, the environmental impact is often perceived as negative, but innovation is underway. Biodegradable plastics are being developed to reduce waste. Although the transition is gradual, the shift toward sustainable options reflects an industry conscious of its footprint. There’s still much to learn and adapt, but the potential is promising.

What is a Plastic Tube and Its Common Uses? - Advantages of Using Plastic Tubes Over Alternatives

| Application | Material Type | Diameter (mm) | Length (m) | Advantages |

|---|---|---|---|---|

| Fluid Transfer | PVC | 25 | 10 | Lightweight, Corrosion-resistant |

| Hydraulic Systems | Polyethylene | 32 | 15 | Flexibility, High pressure tolerance |

| Electrical Insulation | Polyvinyl Chloride | 20 | 5 | Good insulating properties, Durable |

| Food Packaging | Polypropylene | 15 | 8 | Non-toxic, Excellent moisture barrier |

| Medical Applications | Polycarbonate | 10 | 12 | High clarity, Strong and impact-resistant |

Industry Applications and Sectors Utilizing Plastic Tubes

Plastic tubes are versatile products used across various industries. Their lightweight and flexible nature makes them ideal for many applications. In construction, they transport water, air, or other fluids. The durability of these tubes ensures they can withstand harsh environments.

In the food industry, plastic tubes serve crucial roles. They are often used for packaging sauces and other liquids. This helps maintain freshness and quality. However, not all plastic tubes meet safety standards. It's vital to select suitable materials for food contact to avoid contamination.

Healthcare is another critical sector utilizing plastic tubes. From medical tubing to IV bags, their use is fundamental. They provide safe and sterile pathways for liquids. Yet, there remains a concern regarding the long-term effects of plastic. Continuous research is necessary to ensure patient safety and environmental health.

Related Posts

-

Exploring the Future of Best Plastic Tubes Technologies in 2025 and How to Leverage Them

-

How to Choose the Right Plastic Tubes for Your Manufacturing Needs

-

The Versatile World of Plastic Tubes: Innovations and Applications in Everyday Life

-

2025 Top Plastic Tubes Trends and Innovations You Need to Know

-

7 Reasons Why Our Best Cream Tube Outperforms Competitors in 2023

-

How to Choose the Right Plastic Tubes for Your Project in 2025