How to Choose the Right Plastic Tubes for Your Project in 2025

In the rapidly evolving landscape of manufacturing and design, the selection of materials plays a pivotal role in the success of any project. As we advance into 2025, the importance of choosing the right plastic tubes cannot be overstated. Industry expert Dr. Emily Harrington, a renowned specialist in polymer science, emphasizes, "The right choice of plastic tubes can enhance the functionality and durability of your products while also reducing costs." This insight underlines the fundamental role that plastic tubes play across diverse applications, from packaging to construction and beyond.

Selecting the appropriate plastic tubes involves understanding various factors such as material properties, flexibility, and application requirements. With a plethora of options available on the market, it is crucial to assess not only the physical characteristics but also how these materials align with the specific needs of your project. As we delve deeper into the intricacies of plastic tube selection, this guide aims to provide essential considerations and tips to help you make informed decisions that will lead to successful project outcomes.

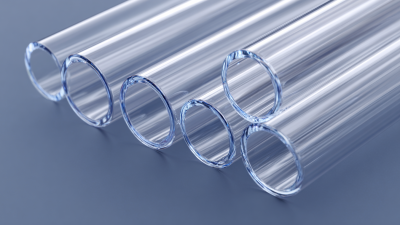

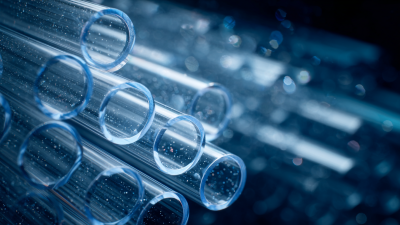

Understanding Different Types of Plastic Tubes Available in 2025

When selecting plastic tubes for your project in 2025, it's essential to understand the variety of options available to maximize functionality and performance. One prominent type is PVC (Polyvinyl Chloride) tubes, known for their durability and resistance to chemicals, making them suitable for various applications, including plumbing and electrical conduits. Additionally, PVC tubes are lightweight and cost-effective, which can be beneficial for large-scale projects.

Another significant option is polyethylene tubes, which are praised for their flexibility and impact resistance. They are widely used in packaging and agriculture, particularly in applications requiring the movement of fluids or gases. Polyethylene tubes come in various densities, with low-density options offering greater flexibility, while high-density versions provide increased strength and rigidity. Understanding these characteristics will help you choose the right type of plastic tube based on your specific needs and project requirements in 2025.

Evaluating the Physical Properties of Plastic Tubes for Your Needs

When selecting plastic tubes for your project in 2025, a critical factor to consider is their physical properties. Different applications require specific characteristics such as durability, flexibility, and resistance to environmental factors. According to a report from the Plastic Pipe and Fittings Association (PPFA), over 70% of industrial pipe specifications now emphasize the importance of material performance in extreme conditions. Understanding attributes such as tensile strength, UV resistance, and thermal stability will help ensure the tubes you choose meet your project’s demands.

Tips: Assess the operating environment of your plastic tubes. If your project involves exposure to sunlight, consider UV-resistant materials. For applications with high temperature fluctuations, focus on tubes with excellent thermal stability to prevent deformation.

Additionally, the diameter and wall thickness of the tubes also play a significant role in their application. A study published by the Society of Plastics Engineers indicated that optimal wall thickness contributes to a balance of strength and lightweight, crucial for reducing material costs without compromising quality. Ensuring you understand the pressure ratings and flow characteristics is essential to prevent system failures and maintain efficiency.

Tips: It’s advisable to conduct a mock-up test with samples to evaluate how chosen tubes perform under your specific conditions before committing to bulk purchases. This approach can save both time and resources in the long run.

How to Choose the Right Plastic Tubes for Your Project in 2025

| Property | Description | Typical Value | Applications |

|---|---|---|---|

| Material Type | The base material used for manufacturing the tube. | PVC, polyethylene, polypropylene | Fluid transfer, packaging |

| Diameter | The internal diameter of the tube, determining flow rate. | 5 mm - 100 mm | Hydraulic systems, pneumatic systems |

| Wall Thickness | Thickness of the walls of the tube affecting pressure tolerance. | 0.5 mm - 10 mm | High pressure applications, structural support |

| Temperature Resistance | Range of temperatures the tube can withstand without failure. | -40°C to 120°C | Electrical insulation, chemical transport |

| Chemical Resistance | Ability to resist degradation from chemicals. | Good to excellent for many chemicals | Chemical industry, laboratory use |

Identifying Industry Standards and Regulations for Plastic Tubes

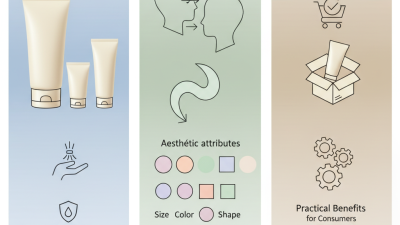

When selecting plastic tubes for your project in 2025, it's essential to understand the industry standards and regulations that govern their use. Various sectors, including manufacturing, healthcare, and construction, have specific requirements for the materials and dimensions of plastic tubes to ensure safety, durability, and compliance with environmental protocols. Familiarizing yourself with standards set by organizations such as ASTM International or ISO can provide valuable insights into the quality and performance characteristics that tubes must meet.

Additionally, it's important to consider regulations that pertain to the specific application of the plastic tubes. For instance, if the tubes will be utilized in food packaging or medical applications, they must comply with stringent health and safety regulations. These regulations ensure that materials do not leach harmful substances and are safe for consumer use. By aligning your project with these industry standards, you can not only enhance the integrity of your product but also facilitate smoother market entry and compliance with relevant legal frameworks.

Plastic Tubes Material Comparison for 2025 Projects

Considering Environmental Impact and Sustainability in Material Choice

When selecting plastic tubes for projects in 2025, it’s vital to prioritize environmental impact and sustainability. The push for eco-friendly materials is more critical than ever, as consumers and manufacturers alike are becoming increasingly aware of the consequences of plastic waste. Look for materials that are recyclable or biodegradable, as these options can significantly reduce your project's carbon footprint. Additionally, consider how the production process of these materials affects the environment. Choosing suppliers who utilize sustainable practices can make a considerable difference.

Tips for selecting sustainable plastic tubes include researching the type of resin used and checking for certifications that indicate eco-friendliness. Opt for tubes made from recycled materials whenever possible, as they help decrease reliance on virgin plastic. Also, evaluate the longevity and durability of the tubes; selecting high-quality options may lead to less waste over time, as they can be reused or serve their purpose longer without degradation.

Furthermore, assess the overall life cycle of the tube. Consider how it will be disposed of at the end of its life and whether the material can be repurposed or recycled easily. Engaging with suppliers that are committed to sustainability can provide options that align with your environmental values while also fulfilling your project requirements, ensuring that your choice impacts positively on the planet.

Comparing Cost and Performance Metrics of Various Plastic Tube Options

When selecting plastic tubes for your project in 2025, understanding the cost and performance metrics of various options is crucial. The initial cost of plastic tubes can vary significantly based on the material used, the manufacturing process, and the quantity purchased. For example, while PVC tubes are often less expensive, polyethylene and polycarbonate options can offer enhanced durability and flexibility for demanding applications. Examining the long-term performance and application requirements is essential, as a higher upfront cost might lead to greater savings in maintenance and replacement over time.

Performance metrics such as pressure tolerance, temperature resistance, and chemical compatibility should guide your choice of plastic tubes. Tubes designed to withstand higher pressures are typically more costly but might be necessary for specific industrial applications. Additionally, consider the environmental impact of the materials; selecting tubes made from recyclable plastics may incur slightly higher initial costs but can contribute to sustainability goals. Ultimately, the right plastic tube not only balances cost against performance metrics but aligns with the specific needs of your project to ensure optimal functionality and longevity.

Related Posts

-

2025 Top Plastic Tubes Trends and Innovations You Need to Know

-

Exploring the Future of Best Plastic Tubes Technologies in 2025 and How to Leverage Them

-

How to Choose the Right Plastic Tubes for Your Manufacturing Needs

-

The Versatile World of Plastic Tubes: Innovations and Applications in Everyday Life

-

What is the Impact of Eco Friendly Cosmetic Packaging on the Environment

-

How to Choose the Best Lotion Tubes for Your Skincare Products