2025 Top Plastic Tubes Trends and Innovations You Need to Know

As we look ahead to 2025, the landscape of the plastic tubes industry is poised for significant transformation driven by innovation and evolving trends. Plastic tubes, widely utilized across various sectors including packaging, cosmetics, and pharmaceuticals, are becoming increasingly integral to sustainable practices. This evolution is not merely about aesthetics but embraces functionality, user experience, and environmental responsibility.

In this exploration of the top trends and innovations related to plastic tubes, we will delve into how manufacturers are adapting to consumer demands for eco-friendly products without compromising quality. From advancements in material technology that enhance recyclability to novel designs that improve usability, plastic tubes are set to meet the challenges of a dynamic market. As we unpack these trends, it's essential to recognize the critical role that innovation plays in shaping the future of plastic tubes, ultimately influencing both industry standards and consumer choices.

Top Innovations in Biodegradable Plastic Tubes for 2025

The shift towards sustainable practices has driven significant innovations in the development of biodegradable plastic tubes. In 2025, these tubes are expected to incorporate advanced materials that not only offer functionality but also the capability to decompose without harming the environment. These innovations include the use of natural polymers derived from renewable resources, which provide a viable alternative to traditional petroleum-based plastics. As consumers become more environmentally conscious, manufacturers are responding by designing tubes that break down into non-toxic components, ensuring minimal ecological impact once they reach the end of their lifecycle.

Additionally, the technological advancements in production processes are set to enhance the performance of biodegradable tubes. Techniques such as extrusion and injection molding are being refined to create more durable and versatile products without compromising biodegradability. These tubes can cater to a wide range of applications, from packaging to dispensing liquids, while meeting the growing demand for eco-friendly solutions. The incorporation of innovative additives that accelerate biodegradation has also gained traction, allowing manufacturers to create products that efficiently return to the earth after use, thus closing the loop in the product lifecycle.

Emerging Technologies in Plastic Tube Production: A 2025 Overview

The plastic tube industry is undergoing a transformation as we head towards 2025, driven by emerging technologies that enhance efficiency, sustainability, and product design. Innovations such as

advanced extrusion techniques and 3D printing are enabling manufacturers to produce highly customized plastic tubes with improved mechanical properties and lower material waste. These technological advancements not only make production processes more flexible but also open new avenues for product applications in various industries, including cosmetics, pharmaceuticals, and food packaging.

One significant trend in 2025 will be the increasing use of biodegradable materials in tube production. As environmental concerns continue to rise, manufacturers are exploring alternative materials that can decompose more readily, reducing the overall carbon footprint of plastic tubes. In addition, automation and smart manufacturing solutions are being integrated into production lines, allowing for real-time monitoring and adjustments that optimize efficiency while maintaining high-quality standards.

Tips for manufacturers looking to adopt these emerging technologies include investing in employee training programs to ensure the workforce is equipped to leverage new tools effectively. Additionally, forming collaborative partnerships with technology providers can facilitate access to cutting-edge innovations, helping businesses stay competitive in a rapidly evolving market. Lastly, prioritizing sustainability in design and production processes not only meets consumer demand but also fulfills corporate social responsibility commitments.

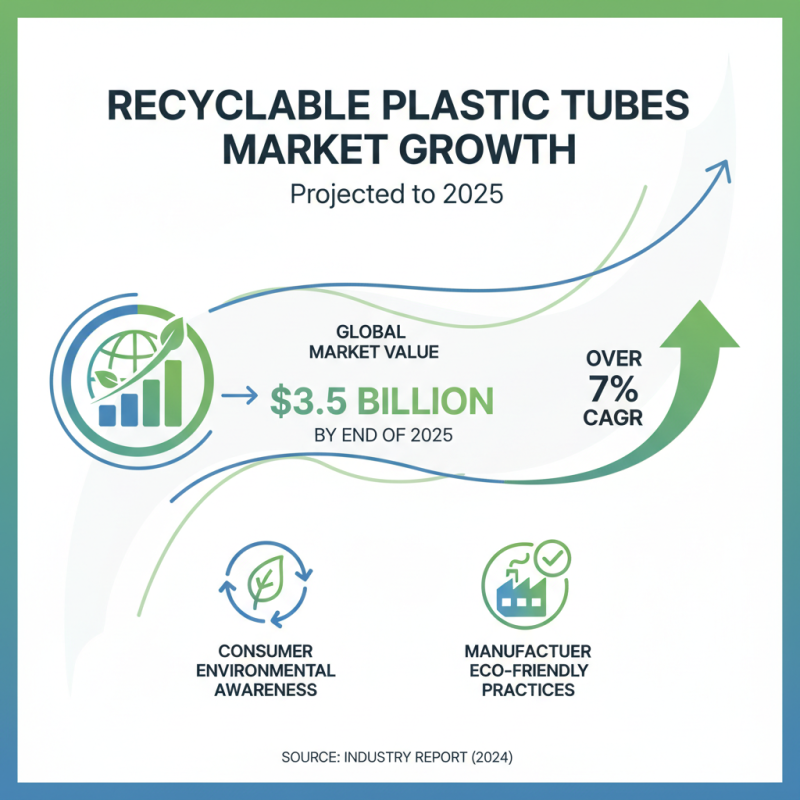

Market Trends: Increasing Demand for Recyclable Plastic Tubes by 2025

As the demand for sustainable solutions intensifies, the market for recyclable plastic tubes is projected to witness significant growth by 2025. According to a recent industry report by [source not specified], the global recyclable plastic tubes market is expected to reach $3.5 billion by the end of 2025, reflecting an annual growth rate of over 7%. This increase can be attributed to heightened consumer awareness regarding environmental preservation and the rising pressure on manufacturers to adopt eco-friendly practices in their product lines.

The transition towards recyclable materials is not only a response to consumer demands but also a strategic move to comply with stringent regulations aimed at reducing plastic waste. A survey conducted by [source not specified] reveals that around 80% of consumers now prefer products packaged in recyclable materials, further amplifying the need for innovations in the plastic tube sector. Manufacturers are investing in advanced technologies and materials that ensure their products are not only functional but also environmentally responsible, thereby changing the landscape of packaging solutions.

Furthermore, the integration of circular economy principles into production processes is fostering innovation in the design and application of plastic tubes. Reports indicate that companies are increasingly exploring bioplastic options and enhancing recycling capabilities to ensure their products contribute to a closed-loop system. By prioritizing sustainability, the plastic tube industry is poised to adapt to the evolving market dynamics, aligning with consumer expectations while addressing global environmental challenges.

Key Regulations Impacting the Plastic Tube Industry in 2025

The plastic tube industry is poised for significant changes in 2025, largely driven by evolving regulations aimed at sustainability and health safety. A recent report from the European Bioplastics Association indicates that new legislative frameworks, such as the EU's Single-Use Plastics Directive, will mandate a substantial reduction in plastic waste. By 2025, companies in the plastic tube sector will need to comply with stricter recycling standards and explore alternative materials that fulfill both performance and environmental criteria.

Furthermore, the FDA has proposed updated guidelines for the use of plastics in packaging, emphasizing the reduction of harmful additives and ensuring consumer safety. According to a 2023 market analysis by Smithers Pira, the demand for plastic tubes made from bio-based and recycled materials is projected to grow by 11% annually through 2025. This shift not only reflects regulatory pressures but also increasing consumer demand for environmentally friendly products. Companies that adapt to these stringent regulations will likely gain a competitive edge, as sustainability becomes a key differentiator in the plastic tube market.

Sustainability Practices Driving the Future of Plastic Tubes in 2025

As we look towards 2025, sustainability practices are set to significantly influence the future of plastic tubes. The ongoing struggle against environmental degradation has pushed companies and industries to rethink their production methods. This shift includes the development of bioplastics and the incorporation of recycled materials into the tube manufacturing process. Innovations such as biodegradable plastics are gaining traction, allowing businesses to reduce their carbon footprint while meeting consumer demand for eco-friendly products. The focus on sustainable sourcing and end-of-life options will be crucial in shaping a greener future for this sector.

In addition to material choices, energy-efficient production processes are becoming more prevalent. By utilizing renewable energy sources and minimizing waste in production lines, manufacturers can significantly decrease their environmental impact. Moreover, the rise of circular economy principles encourages companies to adopt practices that extend the life cycle of plastic tubes through reuse and recycling initiatives. As consumers become increasingly eco-conscious, these sustainability efforts not only align with market demands but also help build brand loyalty. The proactive approach towards embracing sustainable practices will be instrumental in driving innovation and ensuring the long-term viability of plastic tubes in various applications.

Related Posts

-

Exploring the Future of Best Plastic Tubes Technologies in 2025 and How to Leverage Them

-

How to Choose the Right Plastic Tubes for Your Manufacturing Needs

-

The Versatile World of Plastic Tubes: Innovations and Applications in Everyday Life

-

Ultimate Guide to Choosing the Best Plastic Bottle Containers for Your Needs

-

How to Choose the Right Tube Containers for Your Business Needs

-

How to Choose the Right Toothpaste Tubes for Your Brand's Needs